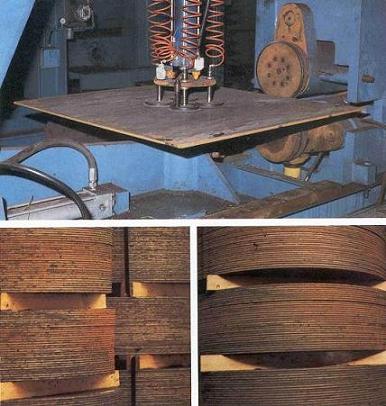

The cylinders are produced starting from high quality steel alloy plate.

The initial material is subject to chemical analyses and mechanical strength tests.

A circular shear transforms the square plate into a disc.

Each disc obtained in this way is controlled dimensionally and the cast identification code stamped onto it.

|

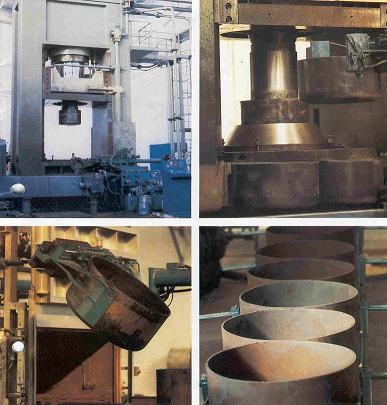

A 1.500 ton hydraulic press transforms the discs into shells by means of succesion of cold-processing operations.

Every shell produced is controlled both dimensionally and for its surface finishing quality. After each drawing, the material is subjected to an intermediate annealing treatment in a controlled atmosphere furnace.

All loading and discharge operations are carried out automatically by electronally controlled handing mechanisms.